Absolute benefits with Solid Heat Flex for surface heating

The absolute benefits of Solid Heat Flex for surface heating are numerous. It is a new material technology, which has earned multiple patents globally. Thanks to its valuable properties: flexibility, durability, high energy efficiency, and embeddability of heat sensors in the material, allowing a wide variety of applications such as automobiles, personal care, industrial, construction, and military. The topic demonstrates and explores the possibility of using Solid Heat Flex in different applications.

Automobile

Some high-end automobile offers a heated seat for consumer convenience and comfort. The heated seat is highly valued in the cold regions during the winter. However, the current issues with heated seats offered by auto manufacturers are slow heat-up time, inefficient energy use, and uneven heat distribution. Manufacturers may have difficulties during the design or production processes since the old materials are inflexible or fragile, which makes it hard to reach the target area for heating. Furthermore, the heat distribution is NOT equal to all targeted surfaces.

Unfixable issues with the old material for the heated seat

Other materials do not provide uniform heat distribution while Solid Heat Flex can equally supply the heat in a given area. Most importantly, material flexibility can be a challenge for an automobile manufacturer since the wire or other materials may disallow installing the materials in the targeted area of the seat.

An example of the absolute benefits of Solid Heat Flex for heated seat

The beauty of Solid Heat Flex is that it provides fast heat-up time compared to the nichrome wire, nano-silver, nanocoating, or other types of heating methods. Also, it uses energy efficiently. Uniform heat distribution is also one of the important factors and Solid Heat Flex ensures uniform heat disbursement while controlling the heat in real-time, ultimately benefiting the consumers.

Battery pre-heating from cold temperature

A battery is one of the critical components for a vehicle on land or in space, yet it is vulnerable to cold temperatures. Especially, a military vehicle crucially needs to consider the operating environment, where it can be deployed in a desert or extremely cold area. There are materials to keep warm for batteries ensuring the vehicle is operable at the cold temperature. However, there are issues with the current materials used for batteries to keep the normal operating temperature in extremely cold or hot temperatures.

The solution to the existing heating pads

The Solid Heat Flex can help to improve heating pad applications using its unique properties: light, flexible, durable, and energy-efficient while the heat is controlled in real time thanks to the heat sensor directly embedded in the material.

Solid Heat Flex for a massage chair

A massage chair provides both movement and heat to relax your muscles. It is helpful especially when you have muscle pains. The combination of movement and heat furthers relaxing your muscles. The Solid Heat Flex for surface heating in this type of application can demonstrate the advantages of the technology.

The main drawback of other materials used as surface heating for a massage chair

The old material used for heating the chair takes too long to heat up, typically it takes 15 minutes reaching to the preset temperature. Also, the heat is not provided equally to the targeted area of the massage chair.

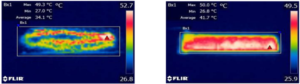

Below is the heat map comparison of nichrome wire vs. Solid Heat Flex

Solid Heat Flex resolves issues

The left heat map photo is taken from a material made of nichrome wire and the right photo is the Solid Heat Flex. It demonstrates the nichrome wire doesn’t provide uniform heat distribution while the Solid Heat Flex distributes the heat equally for the entire area. Also, thanks to the durability and flexibility of Solid Heat Flex, it can be easily adapted to a massage chair application, which requires a durable and flexible operation for massaging.

The above are some of the applications using absolute benefits with Solid Heat Flex for surfacing heating; however, the technology has a huge potential for other target applications that we are unaware of.

Leave a Reply