Wire Heating Elements Issues Resolved by Solid HeatFlex™

Typical Issues With The Wire Heating Elements

Wire Heating Elements apply in commercial, industrial, military, and aerospace for maintaining surface temperature, and the issues associated with wire heating elements have been known for many years.

It provides durability and stability in high-temperature as we understood.

However, there are issues in applying the heating wires to maintain a constant and optimal temperature for a shaped areas, narrow openings, mission-critical devices, securing from the extreme cold temperatures.

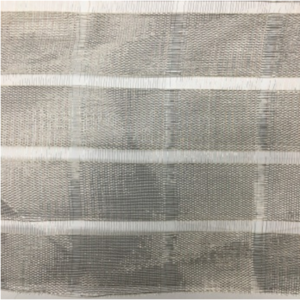

A typical example of surface heating by wire

Today, ships can go through the Arctic due to global warming, resulting in new routes recently developed. The issues are when ships pass through Arctic shipping routes, meeting unexpected issues from the extreme cold temperatures. Here are some recent problems when ships go through an Arctic route:

- The air ventilator may stop working and hurt the people and equipment.

- Iced doors cause a lock.

- Slippery floors

- The ships have adapted using nichrome wires underneath the surface to supply electrical current to maintain the surface temperature, avoiding issues.

However, applying the wire heating elements faces difficulties:

- Shaped areas or narrow openings

- Maintaining temperature above freezing point for critical devices and equipment

- Lightweight requirement or space limitation for a device or equipment with the wire heating element

Applying Nichrome Wire Heating For Maintaining Doors Functioning

Embedding the wire heating elements in the doors is one of the critical applications to keep the door working against freezing temperatures.

Avoiding door blocking by freezing temperature requires the material to be flexible, durable, and energy-efficient, ensuring the contact points get the proper temperature.

However, operating nichrome wire with high current densities may become brittle or reduce its lifespan. Furthermore, running the nichrome wire through the narrow or shaped openings in the door is a challenge.

In general, Nichrome wire can last for many years with proper use and maintenance. However, operating Nichrome wire at high temperatures or with high current densities can reduce its lifespan and lead to thermal degradation. Over time, the Nichrome wire may become brittle or suffer from other forms of degradation.

Resolving Wire Heating Elements by Solid HeatFlex ™

The application requires an alternative solution, that is lighter, energy-efficient, flexible, and durable to replace the surface heating with nichrome wire.

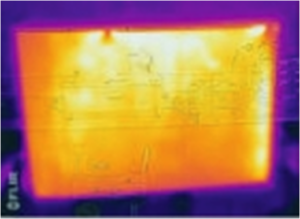

Solid HeatFlex™ resolves most of the issues caused by the nichrome wires since Solid HeatFlex™ is light, energy-efficient, and robust while monitoring and controlling the temperature in real-time with the heat sensors embeddable in the material.

- Lightweight provides an ideal solution for heating shaped and narrow openings.

- More than 20% to 30% energy savings as compared to the Nichrome wires

- Durable from external pressure and forces

- Easy to control and maintain an optimal temperature in real-time

Solid HeatFlex – Before Applying Electrical Current

Solid HeatFlex – When Applying Electrical Current

Leave a Reply